Optimize Maintenance for Seamless Operations

Effective maintenance skill planning is the cornerstone of operational excellence, bridging the gap between workforce capabilities and the complex demands of

Effective maintenance skill planning is the cornerstone of operational excellence, bridging the gap between workforce capabilities and the complex demands of

Maintenance compliance audits are critical checkpoints that protect your business, your team, and your operational integrity in today’s highly regulated industrial

Preventive maintenance checklists are the cornerstone of operational excellence, helping businesses minimize unexpected breakdowns and maximize equipment lifespan while reducing costly

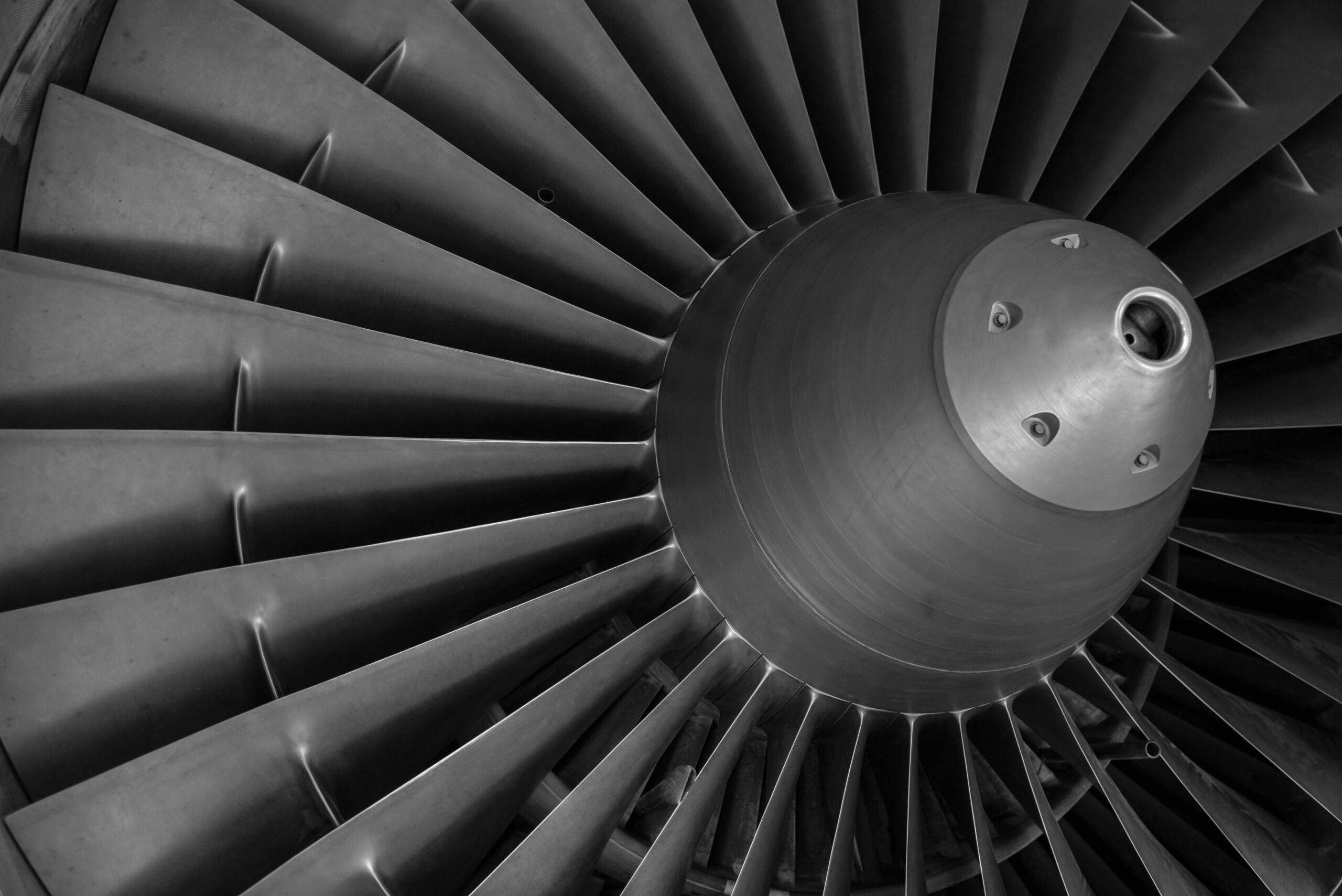

Routine component replacement is the cornerstone of maintaining peak performance in machinery, vehicles, and equipment, ensuring reliability, safety, and cost-effectiveness over

Proactive asset health monitoring transforms maintenance from reactive firefighting into a strategic advantage, reducing unexpected failures and extending equipment lifespan significantly.

Maintenance resource allocation is the strategic backbone of operational excellence, determining how organizations distribute personnel, budget, tools, and time across their

Predictive maintenance is revolutionizing how industries manage equipment, transforming reactive approaches into proactive strategies that prevent costly failures before they occur.

Success isn’t just about achieving goals—it’s about preventing the failures that derail progress before they happen. This comprehensive guide reveals how

Modern maintenance strategies are transforming how industries approach equipment reliability, shifting from reactive fixes to intelligent, data-driven interventions that prevent failures

Spare parts readiness planning stands as a critical pillar in modern operational excellence, directly impacting your bottom line through strategic inventory