Routine component replacement is the cornerstone of maintaining peak performance in machinery, vehicles, and equipment, ensuring reliability, safety, and cost-effectiveness over time.

🔧 Understanding the Critical Role of Preventive Maintenance

Every mechanical system, whether it’s your vehicle, industrial equipment, or home appliances, consists of components with finite lifespans. These parts wear down through normal operation, environmental exposure, and the natural degradation of materials. Ignoring the scheduled replacement of these components doesn’t just risk unexpected failures—it compromises efficiency, increases operational costs, and can pose serious safety hazards.

Preventive maintenance through routine component replacement represents a proactive approach to equipment management. Rather than waiting for catastrophic failures that result in costly downtime and emergency repairs, systematic replacement of wear items keeps systems running at optimal levels. This strategy has proven itself across industries, from automotive maintenance to manufacturing operations, consistently delivering better outcomes than reactive repair approaches.

The Financial Logic Behind Planned Replacements

Many equipment owners view component replacement as an unnecessary expense, particularly when parts still appear functional. However, this perspective overlooks the hidden costs of operating with degraded components. Worn parts force systems to work harder, consuming more energy and placing additional stress on surrounding components.

Consider a simple example: a clogged air filter in a vehicle. While the engine continues running, the restricted airflow forces it to work harder, reducing fuel efficiency by up to 10%. Over thousands of miles, this inefficiency costs significantly more than the replacement filter itself. Similarly, worn bearings create additional friction, generating heat and accelerating wear throughout the entire system.

The financial benefits extend beyond operational efficiency. Planned replacements during scheduled maintenance windows cost substantially less than emergency repairs. You control the timing, can shop for competitive pricing on parts, and avoid premium charges for urgent service. More importantly, you prevent secondary damage that occurs when a failed component damages other parts of the system.

⏰ Identifying Critical Replacement Intervals

Establishing appropriate replacement intervals requires understanding both manufacturer recommendations and your specific operating conditions. Equipment manuals provide baseline schedules based on typical use patterns, but real-world applications often demand adjustments to these standards.

Time-Based vs. Usage-Based Schedules

Replacement intervals typically follow either time-based or usage-based metrics. Time-based schedules replace components after specific periods—monthly, annually, or at other intervals—regardless of actual usage. This approach works well for parts subject to environmental degradation, such as rubber seals, belts, and filters exposed to atmospheric conditions.

Usage-based schedules tie replacements to operational hours, mileage, production cycles, or other activity metrics. This method proves more accurate for components whose wear directly correlates with use intensity. Engine oil, brake pads, and cutting tools fit this category, as their degradation stems primarily from operational stress rather than time passage.

Key Components and Recommended Intervals

While specific intervals vary by application, certain component categories follow general patterns across industries:

- Filters (Air, Oil, Fuel): Every 3,000-15,000 miles for vehicles; quarterly to annually for industrial systems

- Fluids (Engine Oil, Coolant, Hydraulic Fluid): Every 3,000-10,000 miles or 500-2,000 operating hours

- Belts and Hoses: Every 3-5 years or 60,000-100,000 miles

- Brake Components: Every 25,000-70,000 miles depending on driving conditions

- Batteries: Every 3-5 years regardless of apparent functionality

- Spark Plugs: Every 30,000-100,000 miles depending on type

- Timing Belts: Every 60,000-105,000 miles (critical for interference engines)

🚗 Vehicle-Specific Maintenance Strategies

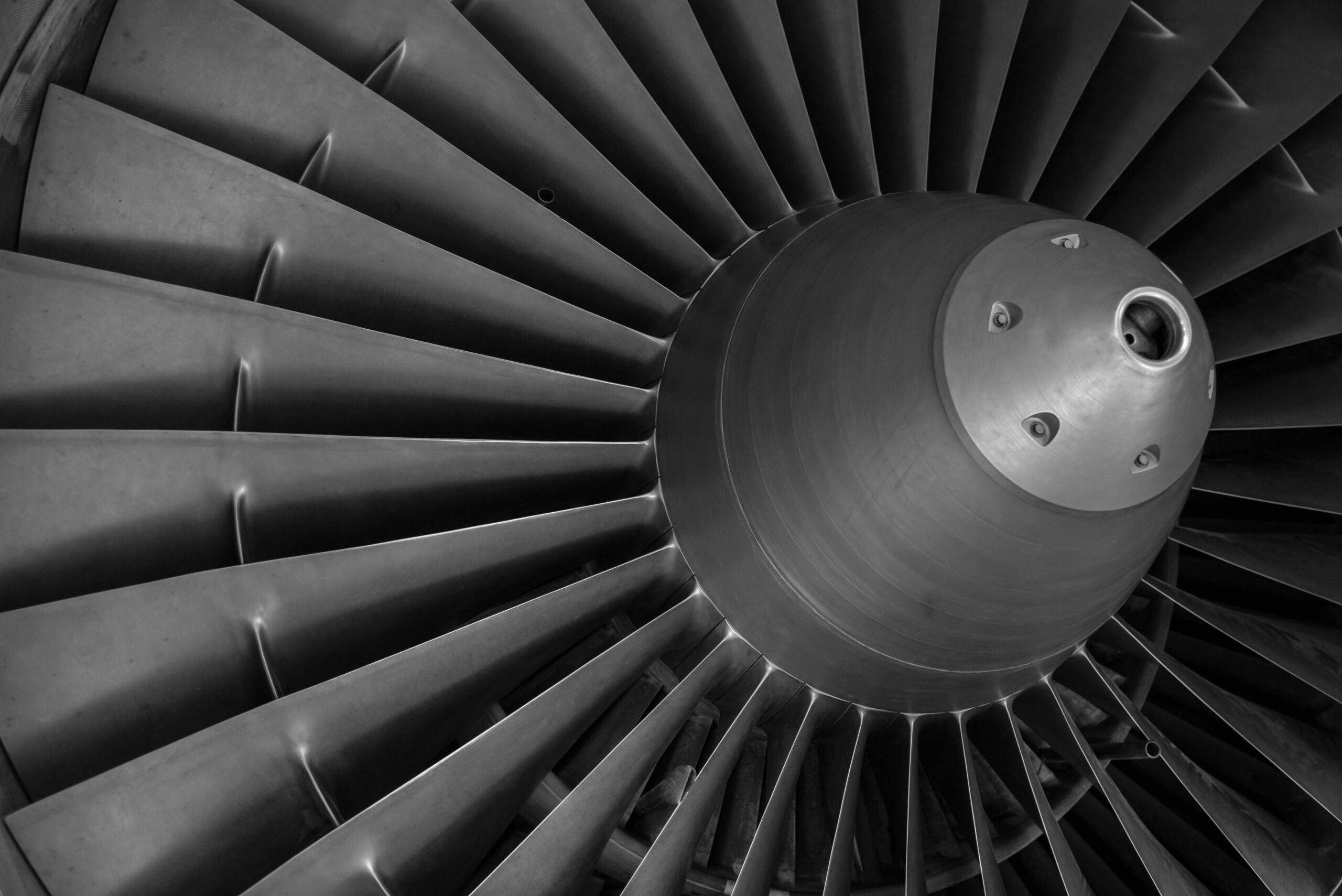

Automotive applications provide an excellent case study in routine component replacement, as neglecting maintenance directly impacts safety, reliability, and resale value. Modern vehicles contain sophisticated systems that require coordinated maintenance approaches.

Engine and Powertrain Components

The engine represents your vehicle’s heart, and its longevity depends heavily on fluid quality and component integrity. Engine oil undergoes thermal and chemical breakdown during operation, losing its lubricating properties and accumulating contaminants. While synthetic oils extend service intervals, no oil lasts indefinitely. Oil filter replacement must accompany every oil change, as saturated filters bypass contaminated oil directly into the engine.

Transmission fluid replacement often gets overlooked, with manufacturers sometimes claiming “lifetime” fluid. However, transmission rebuilds costing thousands of dollars frequently result from degraded fluid that could have been replaced for under $200. Heat, friction, and contamination degrade transmission fluid’s properties, and regular replacement dramatically extends transmission life.

Braking System Maintenance

Brake systems deserve special attention due to their critical safety function. Brake pads wear gradually, but waiting until metal-on-metal contact occurs damages rotors, turning a simple pad replacement into a more expensive job. Regular inspections allow you to replace pads at optimal points, preserving rotor integrity and maintaining consistent braking performance.

Brake fluid absorbs moisture over time, reducing its boiling point and compromising braking effectiveness under demanding conditions. Complete fluid replacement every two to three years maintains system integrity and prevents internal corrosion that can cause expensive caliper and master cylinder failures.

Industrial Equipment: Maximizing Uptime Through Strategic Replacements

Manufacturing and industrial environments face unique challenges where equipment downtime directly impacts productivity and profitability. Systematic component replacement programs form the foundation of reliability-centered maintenance strategies employed by successful operations worldwide.

Building Effective Maintenance Programs

Industrial maintenance programs require detailed component inventories, tracking systems, and clearly defined replacement procedures. Many facilities implement computerized maintenance management systems (CMMS) that schedule replacements, track part histories, and generate work orders automatically when intervals approach.

Successful programs balance manufacturer recommendations with operational experience. Initial schedules follow equipment manuals, but maintenance teams refine these intervals based on actual component performance. This approach identifies parts that consistently fail before scheduled replacement (requiring shorter intervals) and those that show minimal wear at replacement time (potentially extending intervals safely).

Critical Wear Components in Industrial Settings

Industrial equipment contains numerous wear items requiring regular attention. Bearings support rotating equipment and fail progressively, often providing warning signs through increased vibration and noise. Proactive replacement based on vibration analysis or thermographic inspection prevents catastrophic failures that can destroy expensive machinery.

Seals and gaskets prevent fluid leaks and contamination. These components degrade from chemical exposure, temperature cycling, and mechanical stress. Planned seal replacement during scheduled maintenance windows costs a fraction of emergency repairs complicated by fluid contamination and environmental cleanup.

📊 Implementing a Comprehensive Tracking System

Effective component replacement requires systematic tracking to ensure nothing gets overlooked. Whether managing a single vehicle or a fleet of industrial equipment, organized record-keeping separates successful maintenance programs from reactive approaches.

| Tracking Method | Best For | Key Advantages |

|---|---|---|

| Spreadsheet Systems | Small fleets, individual owners | Low cost, customizable, simple implementation |

| CMMS Software | Industrial facilities, large fleets | Automated scheduling, comprehensive reporting, integration capabilities |

| Mobile Apps | Field equipment, distributed assets | Real-time updates, photo documentation, accessibility |

| Paper Logs | Simple applications, backup documentation | No technology requirements, always accessible |

Essential Data Points to Track

Comprehensive maintenance records should capture component identification, installation dates, replacement intervals, actual replacement dates, and any relevant observations. For usage-based schedules, tracking operational hours, mileage, or production cycles proves essential for timing replacements accurately.

Documentation should also include part numbers, suppliers, costs, and technician notes. This information helps identify patterns, evaluate component quality across different manufacturers, and refine replacement intervals based on actual performance data rather than assumptions.

🔍 Recognizing Warning Signs Between Scheduled Replacements

While scheduled replacements prevent most failures, monitoring equipment condition between intervals provides additional protection. Developing awareness of abnormal indicators allows intervention before minor issues become major problems.

Visual Inspection Techniques

Regular visual inspections reveal many developing issues. Look for fluid leaks, worn belts showing cracks or glazing, corroded connections, unusual wear patterns, and physical damage. Many catastrophic failures announce themselves through visible warning signs days or weeks in advance.

Check fluid levels and condition regularly between changes. Oil that appears excessively dark, contains metal particles, or smells burnt indicates problems requiring immediate attention. Coolant should maintain proper color and consistency without oil contamination or rust particles.

Performance Changes as Diagnostic Tools

Equipment performance shifts often signal component degradation. Reduced power, increased fuel consumption, unusual noises, vibrations, or temperature changes all indicate developing issues. Address these symptoms promptly rather than waiting for scheduled maintenance, as they often represent problems requiring immediate intervention.

Modern vehicles provide diagnostic capabilities through onboard computers that monitor system performance. Dashboard warning lights indicate detected issues, but professional diagnostic scans provide detailed information about system status and can identify problems before warning lights illuminate.

Quality Considerations: OEM vs. Aftermarket Components

Component replacement decisions involve quality considerations that significantly impact longevity and performance. Original Equipment Manufacturer (OEM) parts match factory specifications exactly, ensuring compatibility and performance. However, aftermarket alternatives offer cost savings and sometimes superior quality from specialized manufacturers.

Critical components warranting OEM parts include those affecting safety (brake components, steering parts, airbag sensors) and items specifically engineered for your equipment (transmission components, engine internals). For these applications, the quality assurance and perfect fitment of OEM parts justify higher costs.

Aftermarket parts work well for maintenance items like filters, spark plugs, and wear items where multiple manufacturers produce quality options meeting or exceeding OEM specifications. Research reputable brands with positive reviews and appropriate certifications for your application.

💡 Environmental and Operational Factors Affecting Replacement Schedules

Standard replacement intervals assume moderate operating conditions, but harsh environments and demanding applications require schedule adjustments. Equipment operating in extreme temperatures, dusty conditions, high humidity, or corrosive atmospheres experiences accelerated component wear.

Adjusting for Severe Service Conditions

Manufacturers define severe service conditions that warrant shortened maintenance intervals. These typically include frequent short trips, extensive idling, towing, dusty environments, extreme temperatures, and commercial applications. Vehicles and equipment operating under these conditions should follow shortened service intervals, often reducing standard schedules by 30-50%.

Heavy-duty applications place extraordinary stress on components. Commercial vehicles, construction equipment, and industrial machinery operating continuously under load require more frequent attention than consumer-grade equipment used intermittently. Factor operational intensity into scheduling decisions, erring toward conservative replacement intervals for critical applications.

Training and Skill Development for Maintenance Success

Effective maintenance requires knowledge and skills appropriate to your equipment complexity. While professional service remains necessary for specialized procedures, developing basic maintenance capabilities provides significant benefits. Understanding proper procedures ensures correct component installation, prevents damage during replacement, and helps identify quality issues with service providers.

Numerous resources support maintenance skill development. Equipment manuals provide detailed procedures, specifications, and safety precautions specific to your systems. Online video tutorials demonstrate proper techniques for common replacement procedures. Community forums offer advice from experienced users who have encountered similar challenges.

For complex procedures or specialized equipment, professional training courses provide comprehensive instruction. Many manufacturers offer certification programs ensuring technicians understand proper service procedures and have access to technical support resources.

🎯 Building Your Personal Replacement Strategy

Developing an effective component replacement program starts with thorough equipment documentation. Create comprehensive inventories listing all maintenance items, their specifications, and recommended intervals. Organize this information in accessible formats allowing quick reference when scheduling maintenance or ordering parts.

Establish realistic maintenance schedules accounting for your equipment usage patterns, operating environment, and available resources. Set reminders for upcoming maintenance using calendar systems, mobile apps, or automated CMMS notifications. Advanced planning allows ordering parts, scheduling service appointments, and allocating time for maintenance work without rushing or missing intervals.

Budget appropriately for maintenance expenses, treating them as essential operational costs rather than discretionary spending. Allocating funds monthly based on anticipated annual maintenance requirements prevents financial stress when multiple maintenance items coincide. This approach also enables taking advantage of parts sales and bulk purchasing opportunities.

Long-Term Benefits: The Compound Effect of Consistent Maintenance

Commitment to routine component replacement delivers benefits that compound over time. Equipment maintained consistently operates more reliably, experiences fewer unexpected failures, and maintains performance characteristics closer to new condition. These advantages translate into quantifiable financial returns through reduced downtime, lower repair costs, and extended equipment lifespan.

Well-maintained vehicles and equipment retain significantly higher resale values than neglected counterparts. Documentation demonstrating systematic maintenance provides powerful evidence of proper care, commanding premium prices and attracting quality buyers. For businesses, this preservation of asset value impacts balance sheets and provides greater flexibility for equipment replacement decisions.

Perhaps most importantly, proper maintenance provides peace of mind. Confidence in equipment reliability reduces stress, enables better planning, and eliminates the disruption of unexpected breakdowns. This reliability proves invaluable for businesses depending on equipment uptime and individuals relying on vehicles for daily transportation.

The path to maximizing efficiency and longevity through routine component replacement requires initial effort establishing systems and discipline maintaining schedules. However, the rewards—reliability, performance, cost savings, and extended service life—far exceed the investment required. Whether managing industrial equipment, vehicle fleets, or personal transportation, systematic component replacement represents the foundation of successful long-term equipment management. Start today by documenting your maintenance requirements, establishing tracking systems, and committing to the intervals that will keep your equipment performing at peak levels for years to come.

Toni Santos is a maintenance systems analyst and operational reliability specialist focusing on failure cost modeling, preventive maintenance routines, skilled labor dependencies, and system downtime impacts. Through a data-driven and process-focused lens, Toni investigates how organizations can reduce costs, optimize maintenance scheduling, and minimize disruptions — across industries, equipment types, and operational environments. His work is grounded in a fascination with systems not only as technical assets, but as carriers of operational risk. From unplanned equipment failures to labor shortages and maintenance scheduling gaps, Toni uncovers the analytical and strategic tools through which organizations preserve their operational continuity and competitive performance. With a background in reliability engineering and maintenance strategy, Toni blends cost analysis with operational research to reveal how failures impact budgets, personnel allocation, and production timelines. As the creative mind behind Nuvtrox, Toni curates cost models, preventive maintenance frameworks, and workforce optimization strategies that revive the deep operational ties between reliability, efficiency, and sustainable performance. His work is a tribute to: The hidden financial impact of Failure Cost Modeling and Analysis The structured approach of Preventive Maintenance Routine Optimization The operational challenge of Skilled Labor Dependency Risk The critical business effect of System Downtime and Disruption Impacts Whether you're a maintenance manager, reliability engineer, or operations strategist seeking better control over asset performance, Toni invites you to explore the hidden drivers of operational excellence — one failure mode, one schedule, one insight at a time.